Evaporation is a key process in the creation of instant coffee. The journey starts with freshly brewed coffee, which is then sprayed into hot, dry air. This causes the liquid to evaporate quickly, leaving behind tiny particles of coffee. These particles are then dried further to transform them into the familiar powder form we all know and love. The result is a convenient and quick way to enjoy a cup of coffee, perfect for those busy mornings or when you need a caffeine boost on the go.

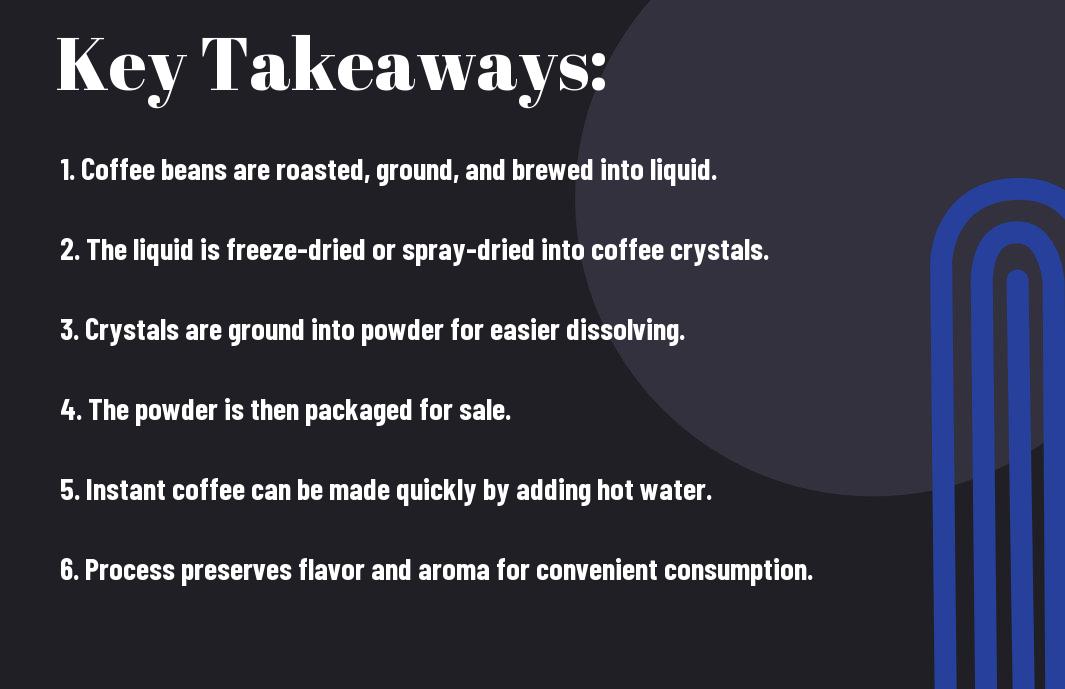

Key Takeaways:

- Extraction Process: Instant coffee is made through an extraction process where water is used to dissolve coffee compounds.

- Freeze-Drying Method: The coffee extract is then passed through a freeze-drying method to remove the water content and create a powder form.

- Aroma Preservation: Instant coffee manufacturers use techniques to preserve the aroma of the coffee during processing.

- Convenience Factor: Instant coffee is popular due to its convenience – just add water to enjoy a quick cup of coffee.

- Long Shelf Life: Instant coffee has a longer shelf life compared to traditional coffee, making it a popular choice for consumers looking for convenience and longevity.

The History of Instant Coffee

Early beginnings: From coffee concentrate to instant powder

For centuries, people have been trying to find ways to enjoy their beloved beverage more conveniently. The earliest form of instant coffee can be traced back to the mid-19th century when coffee concentrate was first developed. This concentrate was created by brewing a strong pot of coffee and then removing the water through a process of dehydration, leaving behind a thick coffee syrup that could be reconstituted with hot water.

The first commercial instant coffee products

One of the pioneers in the commercial production of instant coffee was George Constant Louis Washington, an English chemist living in Guatemala. In 1906, he invented the first mass-produced instant coffee called “Red E Coffee.” This product revolutionized the coffee industry, making it easier and quicker for people to enjoy their favorite brew.

This innovative creation paved the way for the development of other instant coffee products, leading to the diverse range of options available on the market today.

Coffee Bean Selection and Roasting

Choosing the right coffee beans for instant coffee

One of the most crucial steps in creating high-quality instant coffee is the careful selection of coffee beans. The type of beans chosen can significantly impact the flavor profile of the final product. In the process of making instant coffee, Robusta beans are often preferred over Arabica due to their higher caffeine content and stronger, more bitter flavor. Additionally, the beans must be of high quality and free from defects to ensure a delicious and consistent taste in every cup.

Roasting techniques for optimal flavor

Roasting plays a vital role in developing the rich and complex flavors that are characteristic of instant coffee. The roasting process involves heating the green coffee beans to a high temperature to bring out their unique aromas and flavors. Different roasting techniques, such as light, medium, or dark roasts, can create a variety of tastes ranging from fruity and acidic to nutty and chocolatey. Finding the perfect balance of time and temperature is key to achieving an optimal flavor profile for instant coffee.

Selection of the right roast level is crucial in determining the final taste of the instant coffee. Lighter roasts retain more of the beans’ natural flavors and acidity, while darker roasts develop bolder, smokier notes. The roasting process is a delicate art that requires skill and precision to extract the best possible flavors from the coffee beans.

Brewing and Extraction

Not only is the choice of beans crucial in determining the flavor of instant coffee, but the brewing and extraction process also plays a vital role in the final product. Brewing instant coffee involves extracting the soluble flavors and aromas from the coffee grounds, typically through hot water. This process is important for capturing the essence of the coffee beans and creating a flavorful brew.

The importance of brewing temperature and time

| Brewing Temperature | Brewing Time |

| Optimal temperature ranges between 195-205°F | Ideal brewing time varies from 2-5 minutes |

Brewing temperature and time are critical factors that impact the extraction process of instant coffee. The optimal brewing temperature typically falls between 195-205°F to ensure proper extraction of flavors without burning the coffee grounds. Similarly, the brewing time, ranging from 2-5 minutes, determines the strength and richness of the brewed coffee. Finding the right balance between temperature and time is important for achieving a well-rounded and flavorful cup of instant coffee.

Extraction methods: Percolation, infusion, and more

Extraction methods such as percolation and infusion are commonly used in the production of instant coffee. Percolation involves passing hot water through a bed of coffee grounds multiple times to extract flavors and create a concentrated brew. On the other hand, infusion entails steeping the coffee grounds in hot water for a specific period to extract flavors gradually. These methods, along with others, contribute to the variety of instant coffee styles available on the market.

Importance: Understanding the various extraction methods used in brewing instant coffee can help coffee enthusiasts appreciate the complexity and nuances of different coffee flavors. Whether it’s through percolation, infusion, or other techniques, each method brings out unique characteristics in the coffee beans, resulting in a diverse range of instant coffee options for consumers to enjoy.

Freeze-Drying and Spray-Drying

The freeze-drying process: Preserving coffee’s natural flavor

After the brewing process, coffee undergoes a meticulous freeze-drying process to transform it into instant coffee while preserving its natural flavor. In this method, brewed coffee is first frozen into ice crystals and then placed in a vacuum where the ice crystals sublimate, meaning they transition from a solid to a gas without passing through the liquid state. This gentle process helps retain the coffee’s aroma and flavor profile, giving instant coffee a taste that closely resembles freshly brewed coffee.

Spray-drying: A faster and more cost-effective method

Cost-effective and efficient, spray-drying is another popular method used in the production of instant coffee. In this process, brewed coffee is sprayed as a fine mist into a tall drying chamber. As the mist falls, hot air quickly evaporates the liquid, leaving behind tiny particles of dried coffee. While this method may not preserve the coffee’s natural flavor as well as freeze-drying, it is a quicker and more economical option for large-scale production.

Spray-drying allows manufacturers to produce instant coffee in high volumes, meeting the demands of consumers worldwide. While the flavor may not be as robust as freeze-dried coffee, many prefer the convenience and accessibility of spray-dried instant coffee.

Powder Formation and Packaging

Once again, after the coffee extract is dried, the next step in producing instant coffee is to transform it into a fine powder that dissolves easily in hot water. This powder is what gives instant coffee its convenience and shelf-stability. The process of creating the powder involves two main steps: agglomeration and packaging.

Agglomeration: Creating uniform powder particles

Creating uniform powder particles is vital for ensuring that the instant coffee dissolves quickly and evenly when mixed with hot water. Agglomeration is the technique used to achieve this uniformity. During agglomeration, the dried coffee extract is heated and then sprayed with a fine mist of water or steam. This causes the particles to stick together and form larger, more uniform granules. The result is a fine powder that produces a smooth and consistent cup of coffee.

Packaging options: From jars to single-serve sachets

The packaging of instant coffee plays a crucial role in maintaining its freshness and flavor. Instant coffee is available in various packaging options, including glass jars, plastic containers, and single-serve sachets. The choice of packaging depends on factors such as convenience, portability, and shelf-life. Glass jars are popular for home use, as they provide a secure and airtight seal to preserve the coffee’s aroma and flavor. On the other hand, single-serve sachets are ideal for on-the-go consumption, as they are convenient and easy to use.

To ensure the quality of instant coffee, manufacturers pay close attention to the packaging material to prevent moisture and oxygen from degrading the product. Whether in jars or sachets, the packaging is designed to protect the coffee powder from external elements and maintain its freshness until it reaches the consumer.

Quality Control and Safety Measures

Ensuring consistency in flavor and texture

All instant coffee manufacturers prioritize maintaining the same quality and taste in every batch produced. On the journey from coffee beans to your cup, meticulous quality control measures are in place. Every step of the process, from sourcing the beans to the final packaging, is carefully monitored to ensure consistency in flavor and texture.

Quality control experts conduct regular taste tests and evaluations to guarantee that each batch of instant coffee meets the high standards set by the company. These professionals are trained to detect even the slightest variations in aroma, color, and taste, allowing them to make adjustments as needed to maintain the desired quality.

Meeting food safety standards and regulations

An vital aspect of instant coffee production is meeting stringent food safety standards and regulations. The manufacturing facilities adhere to strict guidelines to ensure the safety and quality of the final product. From proper handling of raw materials to sanitization of equipment and packaging, every aspect is carefully regulated.

Safety measures also include regular inspections by governing bodies to assess the manufacturing process and ensure compliance with food safety regulations. By following these strict protocols, instant coffee manufacturers can guarantee that their products are safe for consumption and meet the highest quality standards.

Final Words

With this in mind, understanding the process behind the production of instant coffee allows us to appreciate the convenience and ingenuity that goes into making this popular beverage. If you’re curious to learn more about the intricate steps involved in creating instant coffee, you can explore further by checking out What is the process behind the production of instant coffee?. Next time you enjoy a cup of instant coffee, you’ll have a newfound appreciation for the craftsmanship and technology that make it possible.

FAQ

Q: What is instant coffee?

A: Instant coffee is a type of coffee that is derived from brewed coffee beans. It is processed into a dry, soluble form that can be quickly reconstituted in hot water to create a cup of coffee.

Q: How is instant coffee made?

A: Instant coffee is made through a process called freeze-drying or spray drying. In freeze-drying, brewed coffee is frozen into slush, then cut into granules and dried at low temperatures. In spray drying, brewed coffee is sprayed as a fine mist into hot, dry air to remove the moisture content and form small coffee particles.

Q: What are the advantages of instant coffee?

A: Instant coffee offers convenience, longer shelf life, and easy preparation compared to traditional brewed coffee. It is also convenient for on-the-go situations, as all you need is hot water to enjoy a quick and easy cup of coffee.